How HordRT’s Material-Specific Technology is Revolutionizing Injection Molding Service

Introduction

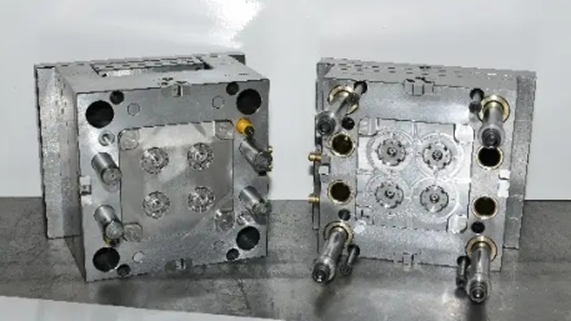

HordRT‘s innovative approach to injection molding service is showcased through their advanced material-specific technology. The development of specialized screw and barrel assemblies addresses critical challenges in the industry, including material waste and quality consistency. By focusing on material-specific solutions and expanding quick-change capabilities, HordRT is setting new standards for efficiency and versatility in manufacturing.

Enhancing Efficiency with Material-Specific Assemblies

HordRT’s material-specific technology enhances efficiency by reducing material waste during injection molding service. Traditional methods often involve extensive cleaning between different resin runs, leading to unnecessary waste. HordRT’s advanced screw and barrel assemblies are designed for specific materials, facilitating quicker transitions and minimizing the need for extensive cleaning. This innovation not only conserves resources but also streamlines the manufacturing process, making it more efficient overall.

Achieving Consistent Quality with Specialized Technology

Consistency in quality is essential for injection molding service, and HordRT’s technology excels in this area. By utilizing material-specific screw and barrel assemblies, HordRT ensures that each resin is processed under optimal conditions. This consistency in processing results in high-quality output across various materials. Manufacturers can rely on HordRT’s technology to deliver reliable and uniform results, enhancing their production capabilities and product quality.

Broadening Quick-Change Capabilities

HordRT’s dedication to expanding its quick-change solutions demonstrates their commitment to versatility in injection molding service. The company’s ongoing efforts to cover a wider range of materials with their technology highlight their responsiveness to industry needs. By broadening their quick-change solutions, HordRT provides manufacturers with greater flexibility, allowing them to adapt to diverse production requirements and material specifications.

Conclusion

HordRT’s advanced material-specific technology is transforming the injection molding service landscape. By reducing material waste and ensuring consistent quality through specialized screw and barrel assemblies, HordRT offers significant improvements in efficiency and precision. As the company continues to expand its quick-change solutions, manufacturers can benefit from enhanced flexibility and performance. HordRT’s innovative technology is setting a new standard in the industry, reaffirming their position as a leader in optimizing manufacturing processes.