Within the world associated with contemporary production, ultrasonic welding sticks out like a critical technologies which has changed exactly how sectors strategy becoming a member of supplies. Through consumer electronics in order to auto elements, ultrasonic welders have grown to be important resources, because of their own effectiveness, accuracy, as well as flexibility ultrasonic welder. This short article goes to the globe associated with ultrasonic welders, discovering their own concepts, programs, advantages, as well as long term potential customers.

What’s Ultrasonic Welding?

Ultrasonic welding is really a procedure accustomed to sign up for supplies, usually alloys or even thermoplastics, utilizing high-frequency ultrasonic vibrations. In contrast to conventional welding techniques which depend on warmth produced through electric currents or even fire, ultrasonic welding utilizes seem surf to produce a local burning stage exactly where supplies tend to be became a member of.

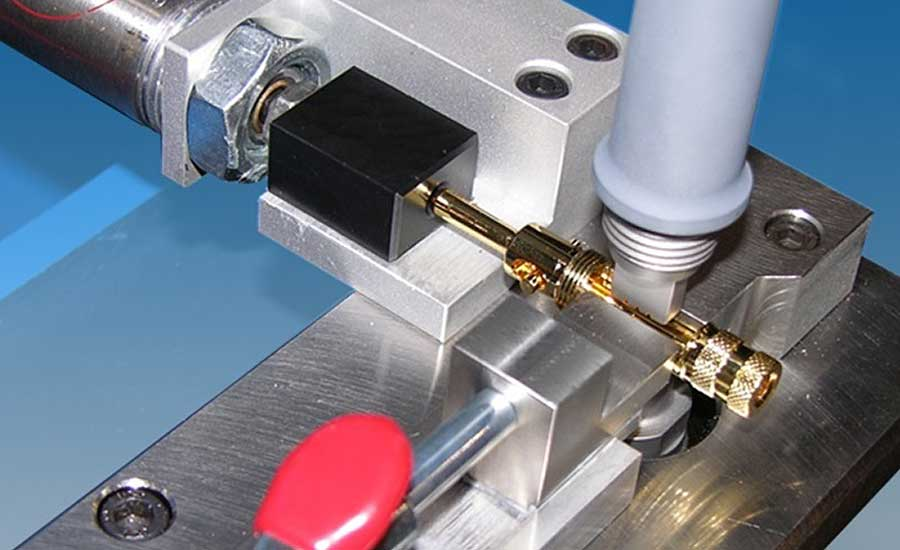

From it’s primary, the actual ultrasonic welding procedure entails the next crucial elements:

Ultrasonic Electrical generator: Changes electrical power in to ultrasonic vibrations.

Transducer: Changes the actual electric transmission in to mechanised vibrations.

Sonotrode (or Horn): Amplifies the actual vibrations as well as is applicable these phones the actual supplies to become welded.

Anvil: Facilitates the actual materials throughout the welding procedure as well as guarantees correct position.

So how exactly does Ultrasonic Welding Function?

The actual ultrasonic welding procedure starts using the ultrasonic electrical generator generating high-frequency electric indicators, usually within the selection of 20 kHz in order to seventy kHz. These types of indicators tend to be changed into mechanised vibrations through the transducer. The actual vibrations tend to be after that increased through the sonotrode as well as put on the actual supplies becoming became a member of.

Once the ultrasonic vibrations tend to be used, these people produce local warmth via rubbing in the user interface from the supplies. This particular warmth is enough in order to dissolve the actual materials in the user interface, developing the solid-state relationship since the materials cools as well as solidifies. The procedure is very quick, frequently getting just a couple milliseconds to accomplish.

Programs associated with Ultrasonic Welding

Ultrasonic welding is utilized throughout numerous sectors because of its capability to sign up for supplies effectively with minimum energy harm. Here are a few significant programs:

Consumer electronics: Within the consumer electronics business, ultrasonic welding can be used with regard to becoming a member of good cables as well as terminals within elements such as devices, fittings, as well as signal planks. It’s accuracy as well as reduced warmth era are very important with regard to stopping harm to sensitive digital elements.

Auto: Auto producers make use of ultrasonic welding with regard to putting together elements for example energy program components, airbag fittings, as well as electric makes use of. The procedure offers powerful as well as dependable important joints which satisfy the strict needs associated with auto programs.

Healthcare Products: Ultrasonic welding is fantastic for the actual healthcare gadget business, exactly where it’s accustomed to put together aspects of products such as catheters, syringes, as well as medical devices. The actual technologies helps to ensure that the actual elements tend to be became a member of without having using adhesives or even extra supplies, that is essential with regard to sustaining the actual sterility as well as performance associated with healthcare products.

Product packaging: Within the product packaging business, ultrasonic welding can be used with regard to closing plastic material product packaging supplies. It offers the thoroughly clean as well as effective method to close off deals with no need with regard to warmth or even chemical substances, that is essential for sustaining the caliber of the actual material.

Aerospace: Aerospace programs take advantage of ultrasonic welding with regard to becoming a member of light-weight supplies as well as elements utilized in plane as well as spacecraft. The actual technologies provides accuracy as well as power which are required for conference the actual thorough requirements associated with aerospace architectural.

Advantages of Ultrasonic Welding

The actual ownership associated with ultrasonic welding provides several benefits more than conventional becoming a member of techniques:

Pace: Ultrasonic welding is really a quick procedure, frequently finishing important joints within milliseconds. This particular higher pace means elevated manufacturing effectiveness as well as decreased period occasions.

Minimum Warmth Era: In contrast to conventional welding techniques that need considerable warmth, ultrasonic welding creates local warmth just in the user interface from the supplies becoming became a member of. This particular reduces energy distortion as well as harm to encircling places.

Accuracy: The actual technologies enables exact manage within the welding procedure, resulting in constant as well as high-quality important joints. A chance to use good supplies as well as elements causes it to be well suited for sectors along with strict high quality needs.

Absolutely no Consumables: Ultrasonic welding doesn’t need extra supplies such as solder or even adhesives. This particular removes the requirement with regard to consumables as well as decreases waste materials, adding to financial savings as well as environment advantages.

Decreased Power Usage: The procedure uses much less power when compared with conventional welding techniques, which makes it a far more environmentally friendly option with regard to producers.

Problems as well as Factors

Whilst ultrasonic welding provides several benefits, additionally, it includes its group of problems:

Materials Compatibility: Not every supplies tend to be ideal for ultrasonic welding. The procedure is actually mainly efficient along with alloys as well as thermoplastics, and it is usefulness can differ in line with the material’s qualities.

Gear Expenses: The first expense within ultrasonic welding gear could be greater when compared with a few conventional welding techniques. Nevertheless, the actual long-term advantages when it comes to effectiveness as well as decreased materials expenses frequently outweigh the first expenses.

Combined Power: Whilst ultrasonic welding offers powerful important joints, the effectiveness of the actual relationship depends upon numerous elements, such as materials qualities as well as procedure guidelines. Making sure optimum configurations is vital with regard to attaining the required combined power.

The near future associated with Ultrasonic Welding

Because technologies is constantly on the progress, ultrasonic welding is actually likely to develop as well as increase it’s programs. Improvements within ultrasonic welding gear as well as methods will probably improve it’s abilities, which makes it ideal for a level wider selection of supplies as well as programs.

Integration along with Automation: The actual integration associated with ultrasonic welding along with robot automation is actually likely to improve it’s effectiveness as well as accuracy. Automatic techniques may enhance regularity as well as decrease human being mistake within the welding procedure.

Sophisticated Supplies: Investigation in to brand new supplies as well as composites can lead to the actual improvement associated with ultrasonic welding methods that may manage the broader number of supplies. This may open brand new possibilities within sectors for example aerospace as well as green power.

Improved Manage Techniques: Improvements in charge techniques as well as devices will probably enhance the accuracy as well as versatility associated with ultrasonic welding, permitting more complicated as well as challenging programs.

Summary

Ultrasonic welding has built by itself like a transformative technologies within contemporary production, providing unequalled pace, accuracy, as well as effectiveness. Through consumer electronics in order to aerospace, it’s programs period an array of sectors, adding to improvements as well as breakthroughs throughout numerous areas. Whilst problems stay, continuing investigation as well as technical breakthroughs guarantee to help boost the abilities as well as programs associated with ultrasonic welding. Because sectors still look for effective as well as environmentally friendly options, ultrasonic welding appears ready in order to perform the critical part within framing the near future associated with production.